INSPECTION SERVICES

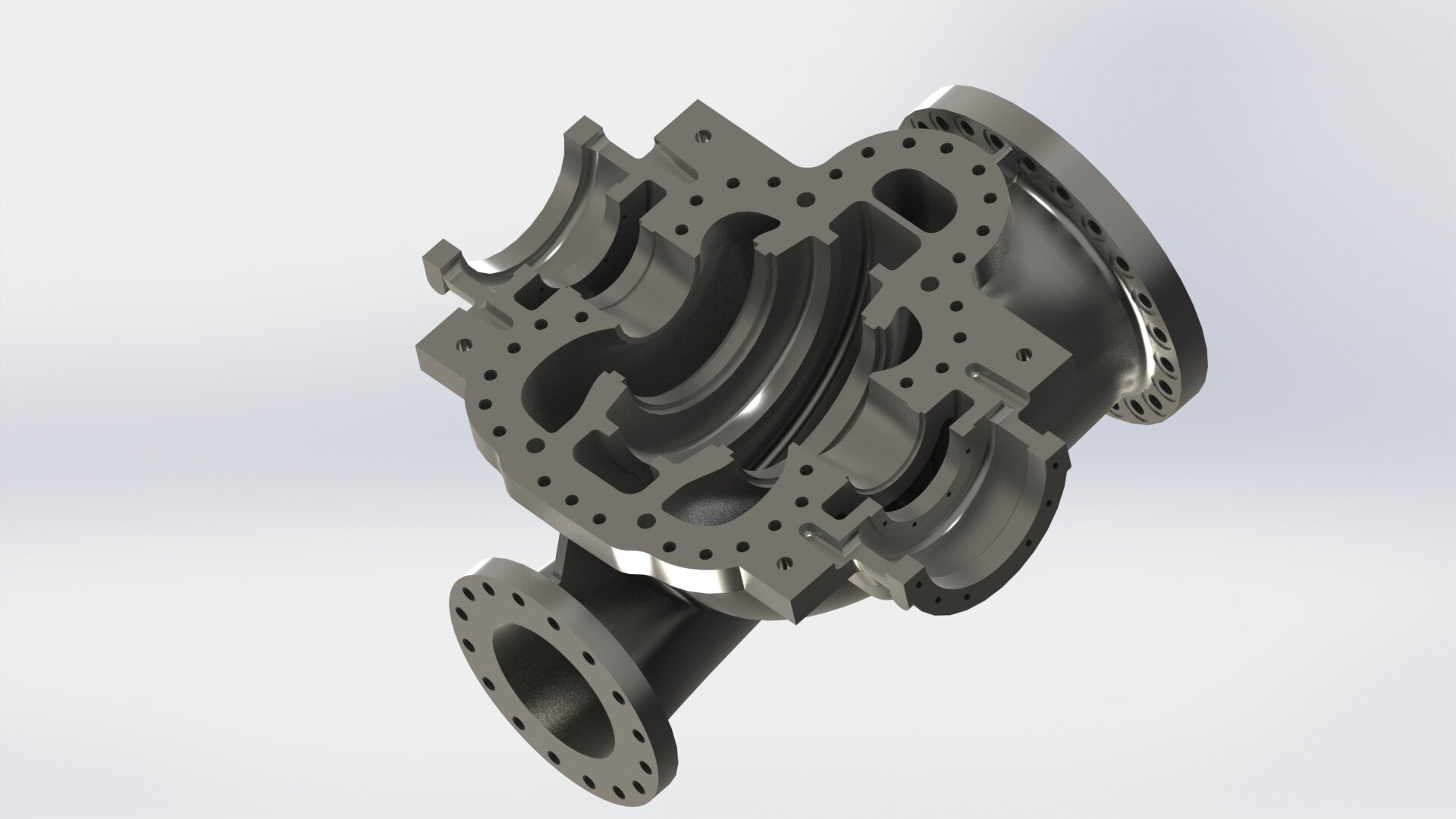

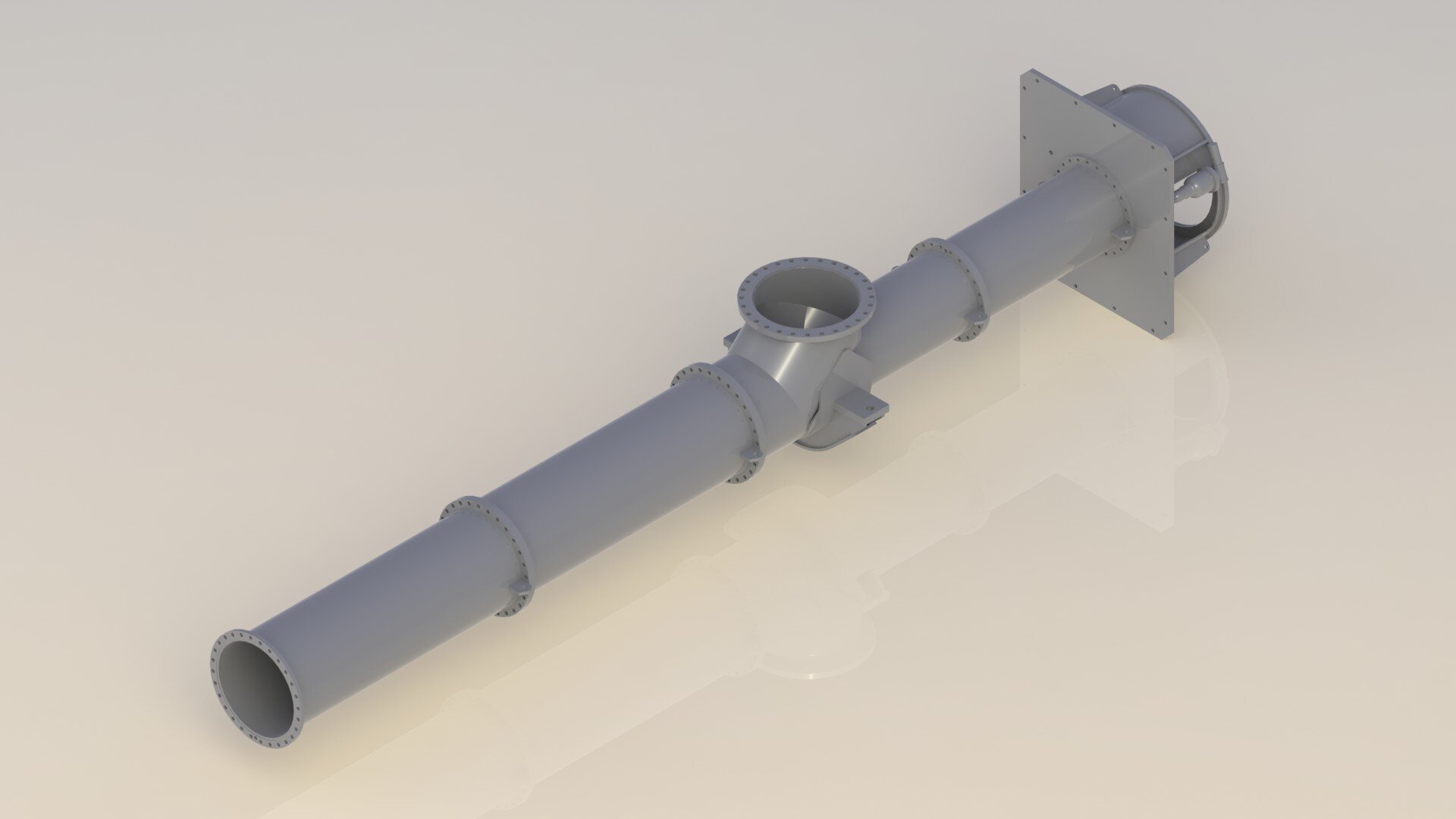

The pump repair process foundation is a thorough and documented inspection. After the pump arrives, it is sand blasted to remove any coatings, scale, or rust. Then, one of our engineers will perform a visual and dimensional check of all vital features and components. This includes all fits, running clearances, seal faces, and run outs of the shaft at a minimum.

After the inspection is completed, the engineer and our quoting department will develop a work scope detailing new components and repairs necessary to return your equipment to like-new condition.

After the repair of your pump, the inspection data along with the "as built" condition will be included in a final report. The final report includes an executive summary, the "as found" and "as built" conditions, as well as the balance reports for any rotating equipment.

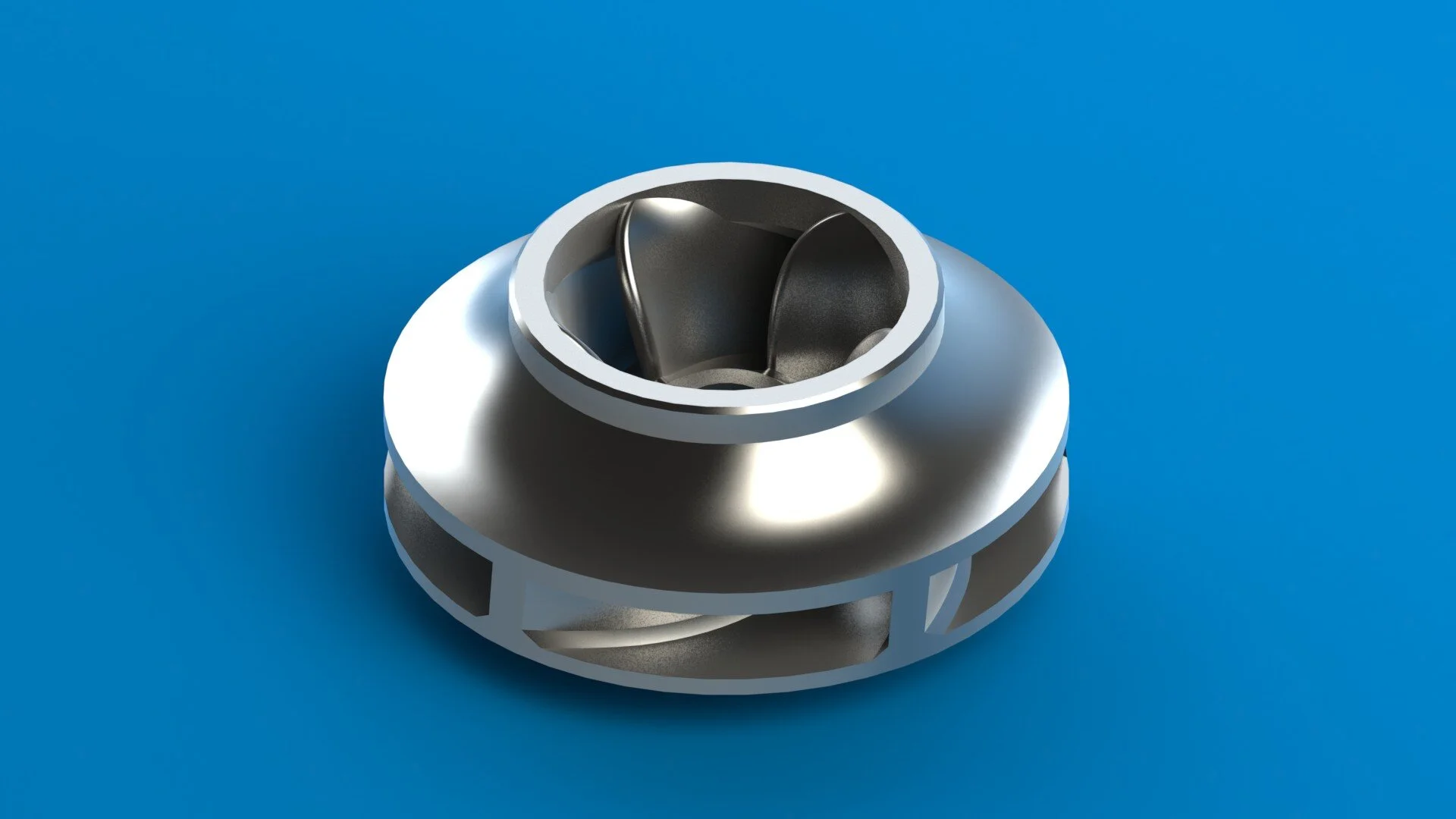

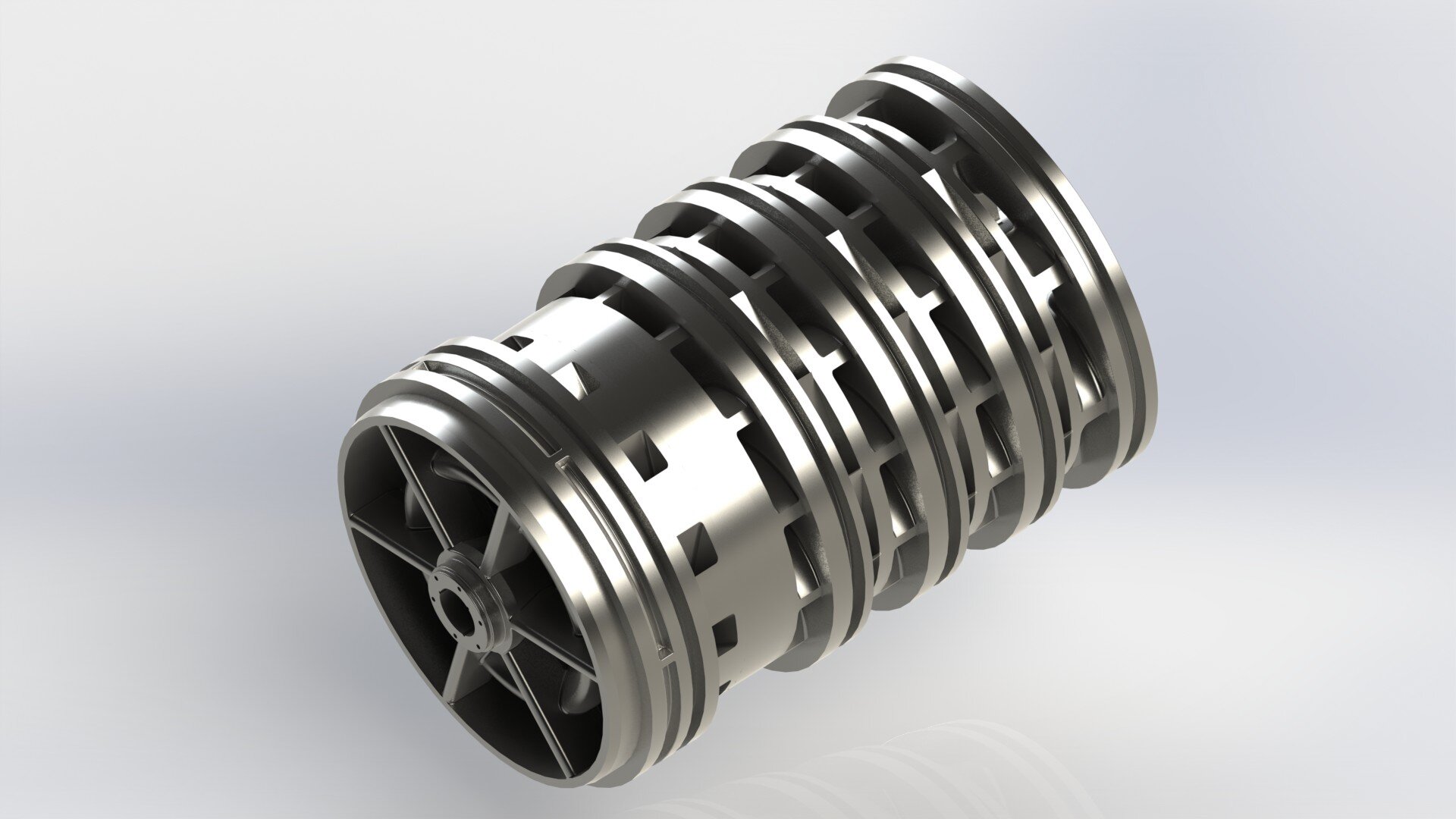

TRADITIONAL REVERSE ENGINEERING

As an independent repair shop, reverse engineering is at the heart of what we do. Understanding the common design elements across OEMs gives us a unique knowledge of the reverse engineering process.

RER has 12 Mechanical Engineers on staff. Our engineers act as project managers for every pump that comes in our door. From machining prints and repair specifications to purchasing and sub-contract machining, the Project Engineer is “plugged in” on every facet of the job. This integrated approach reduces lapses in the repair process, all leading to better on time deliveries.

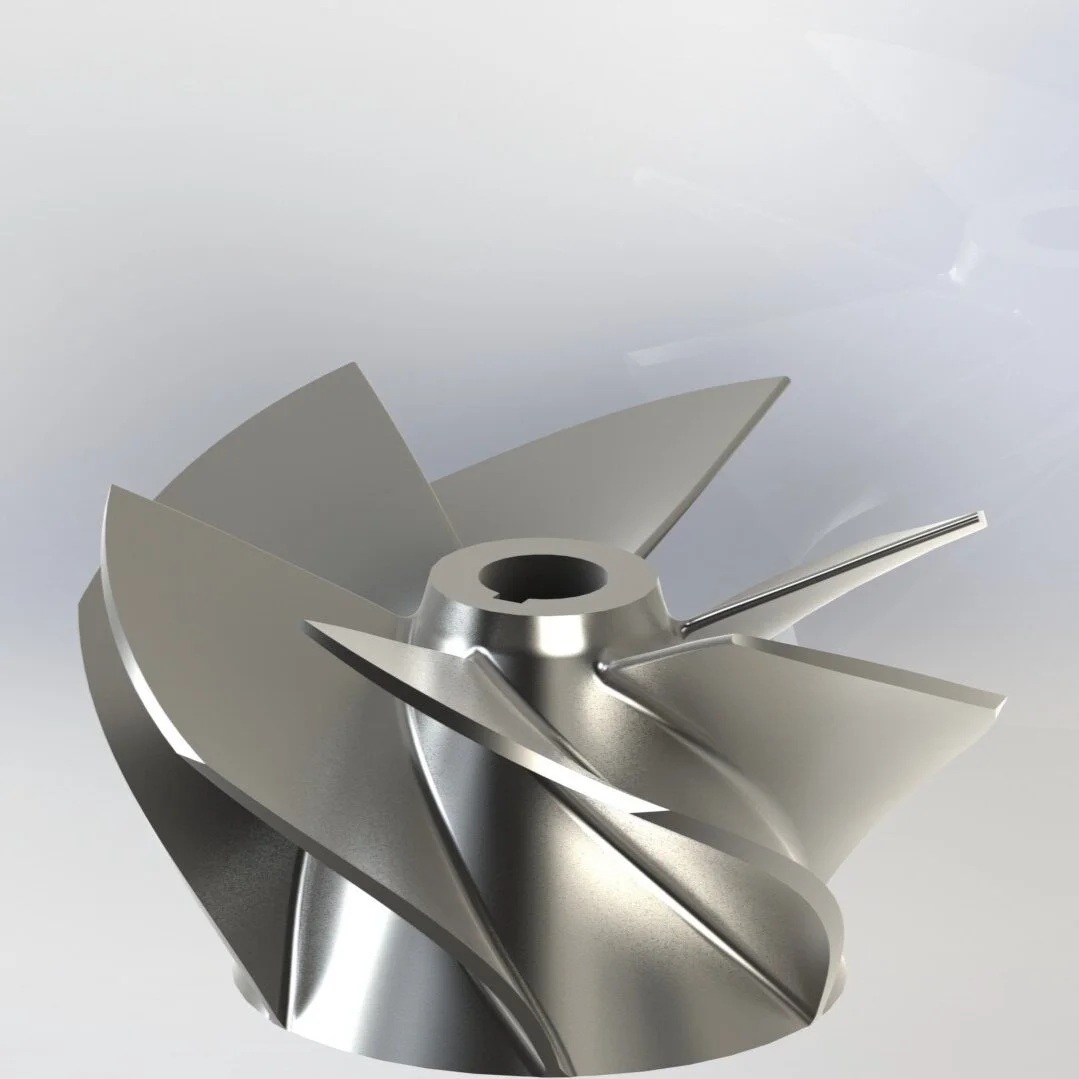

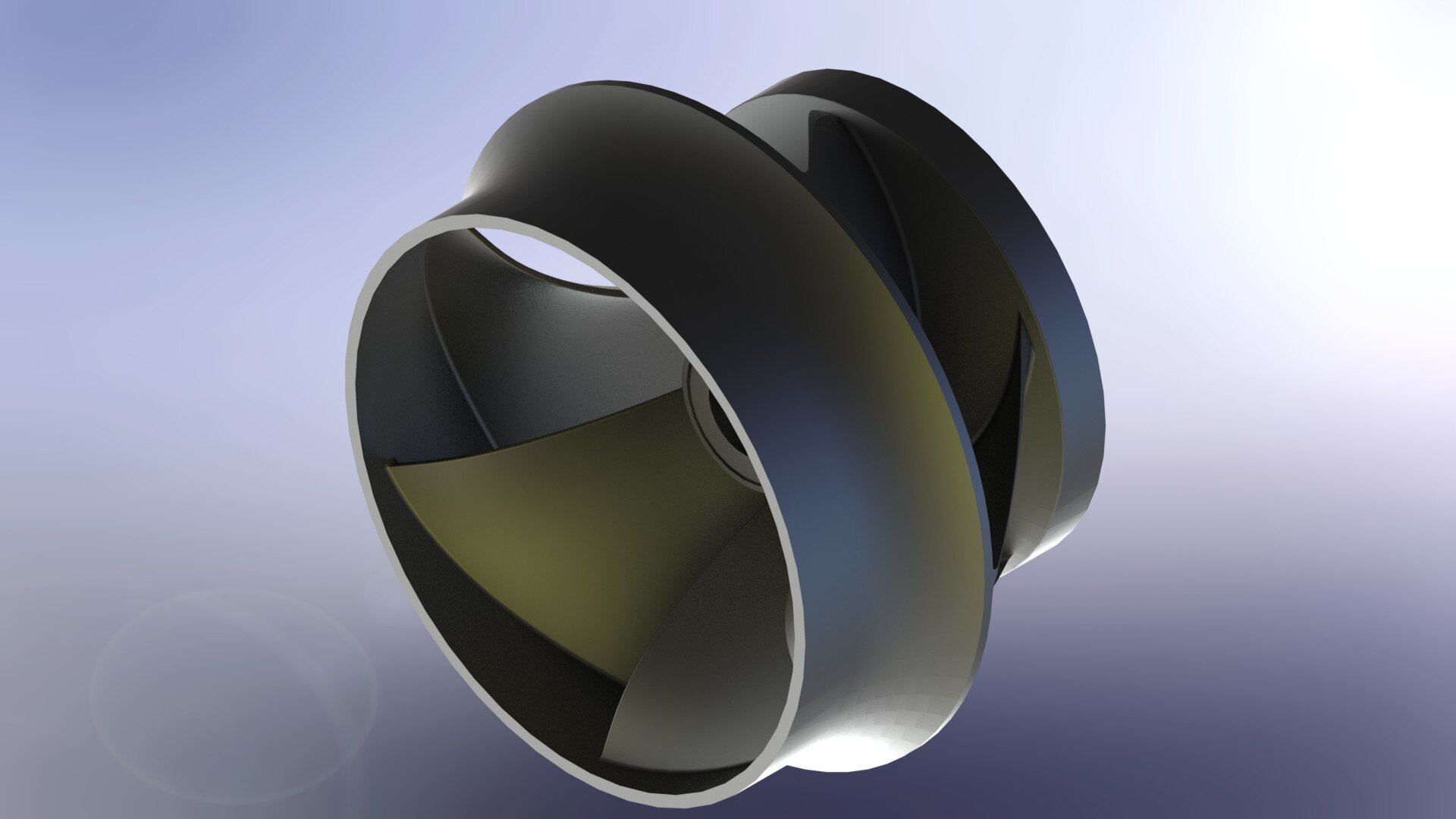

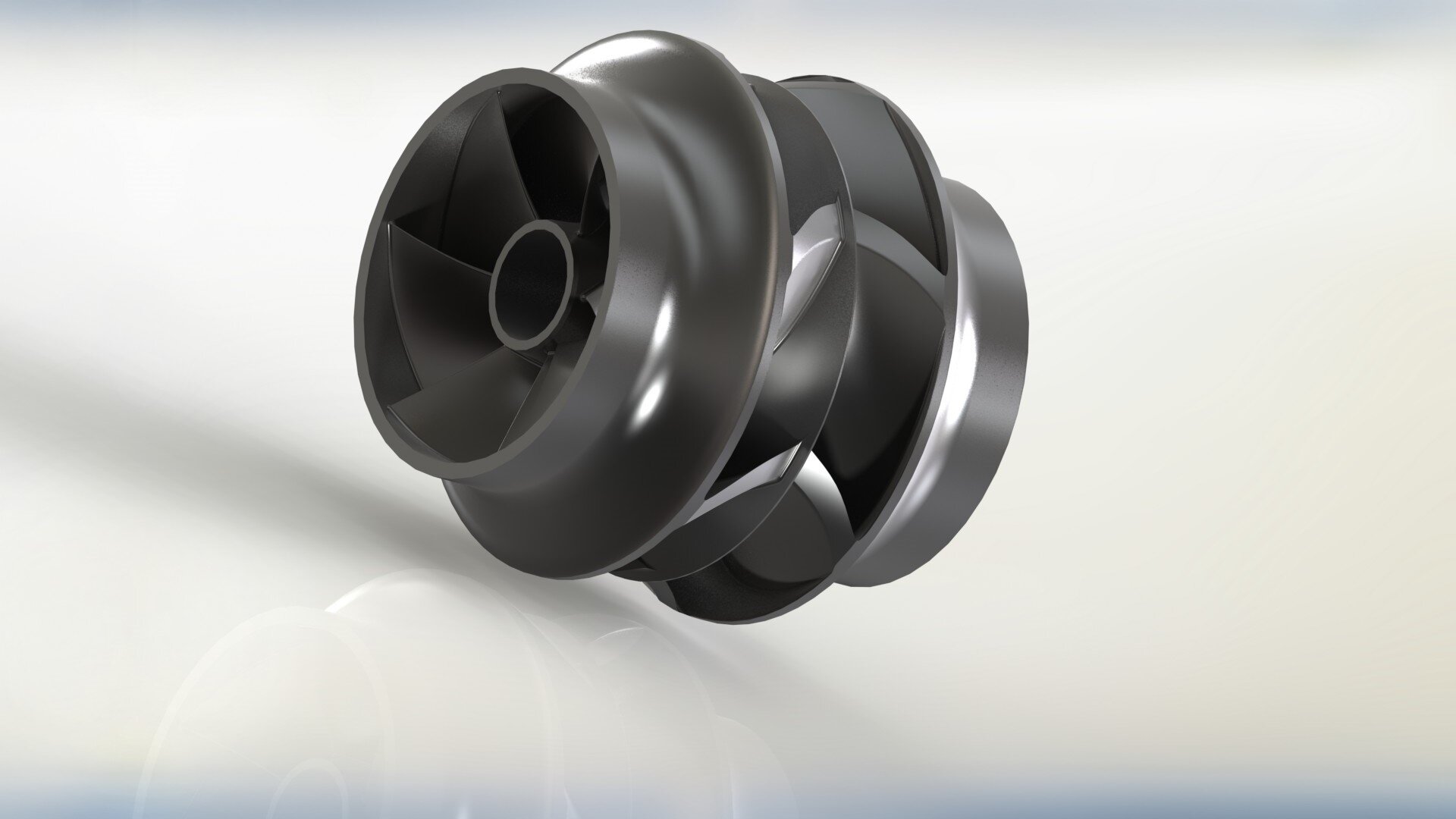

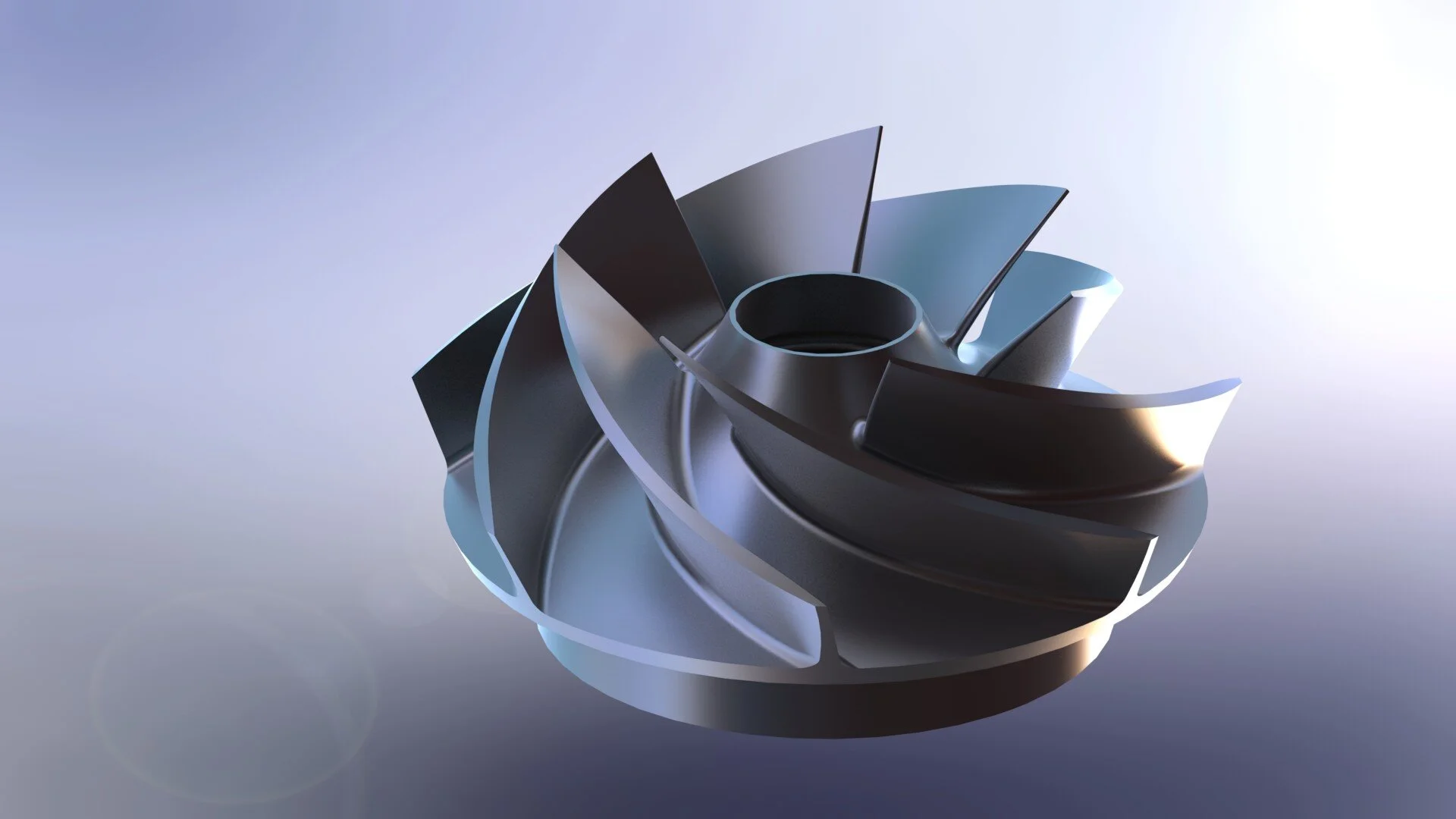

SCANNING AND MODELING

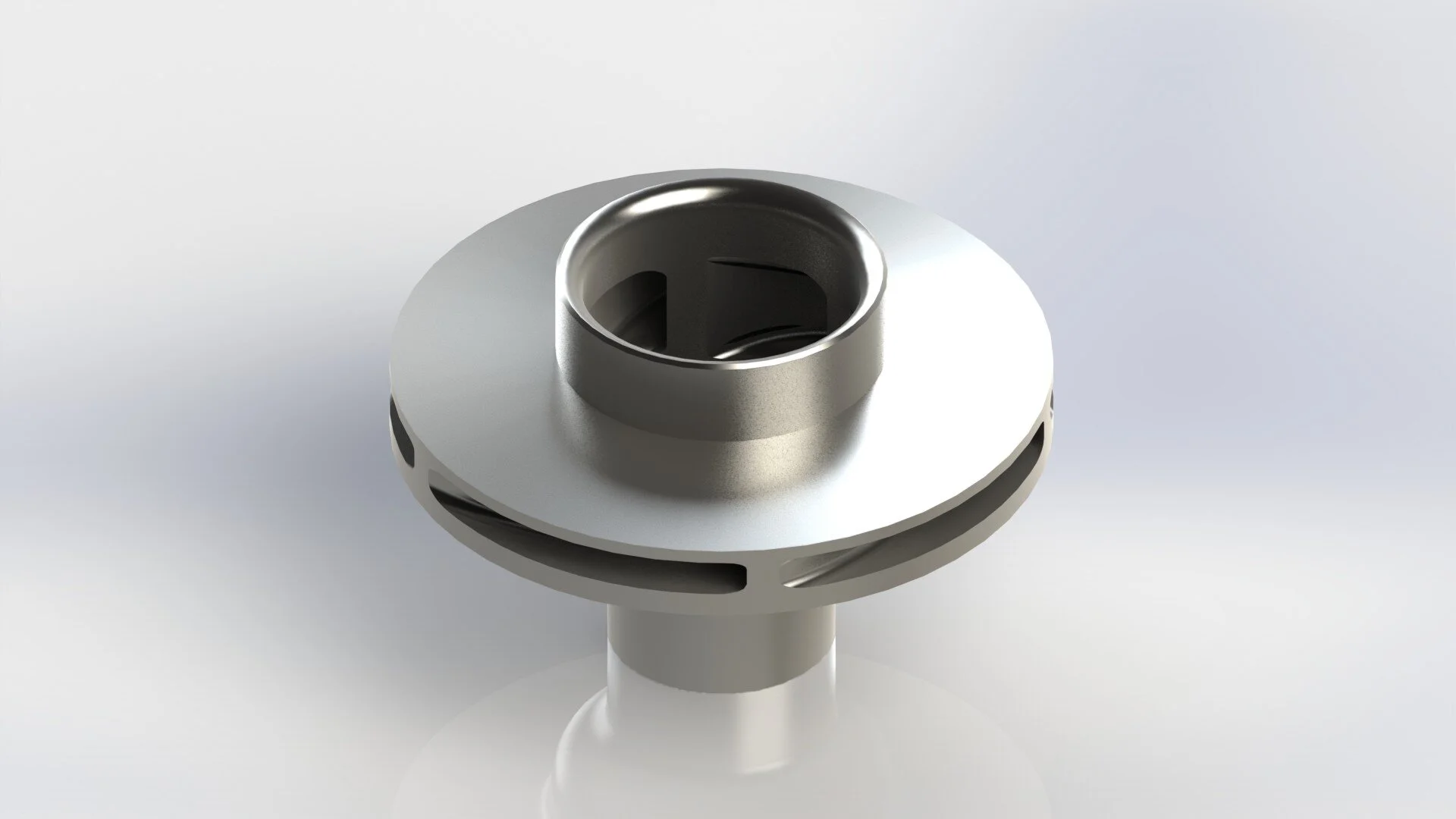

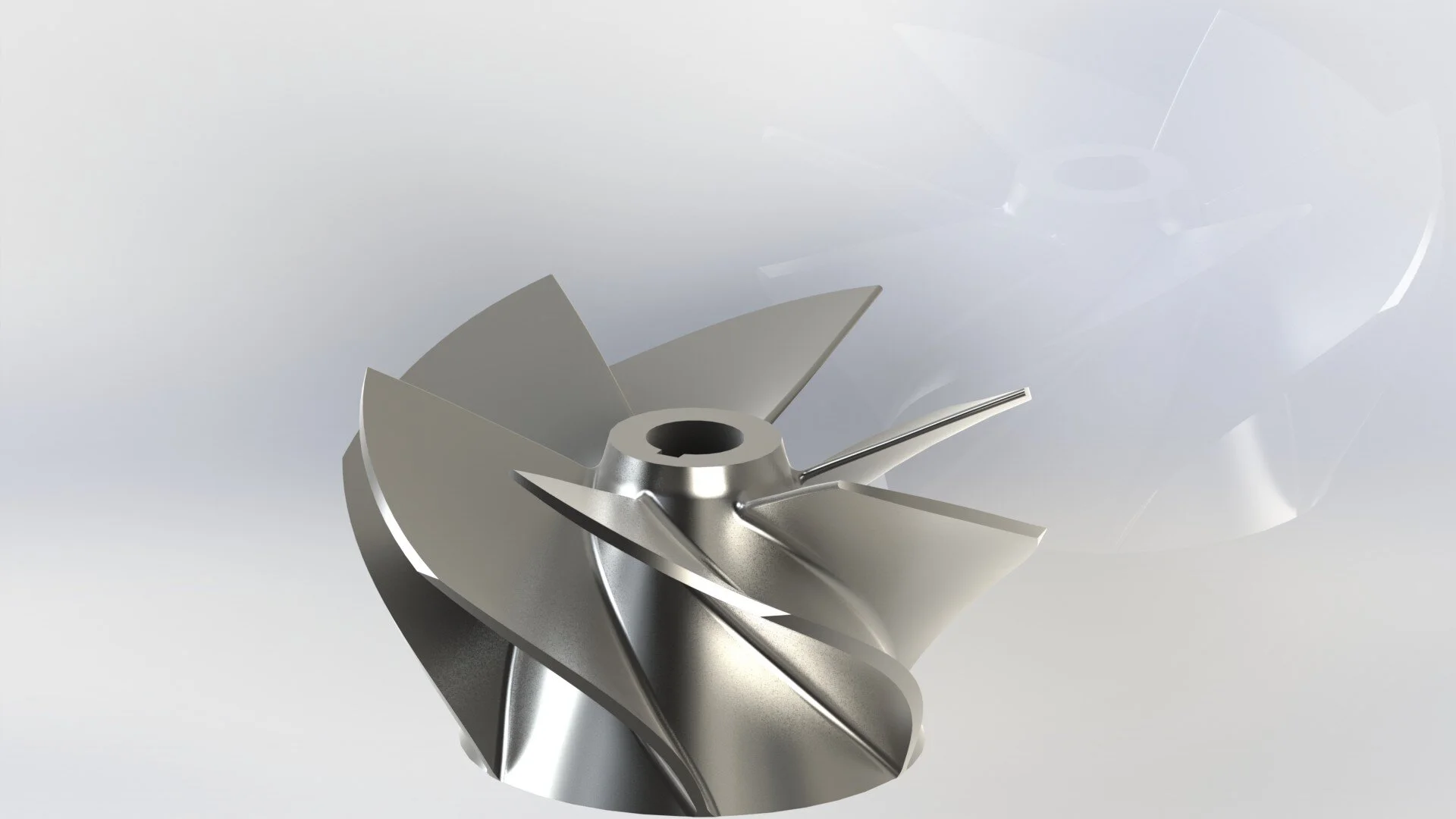

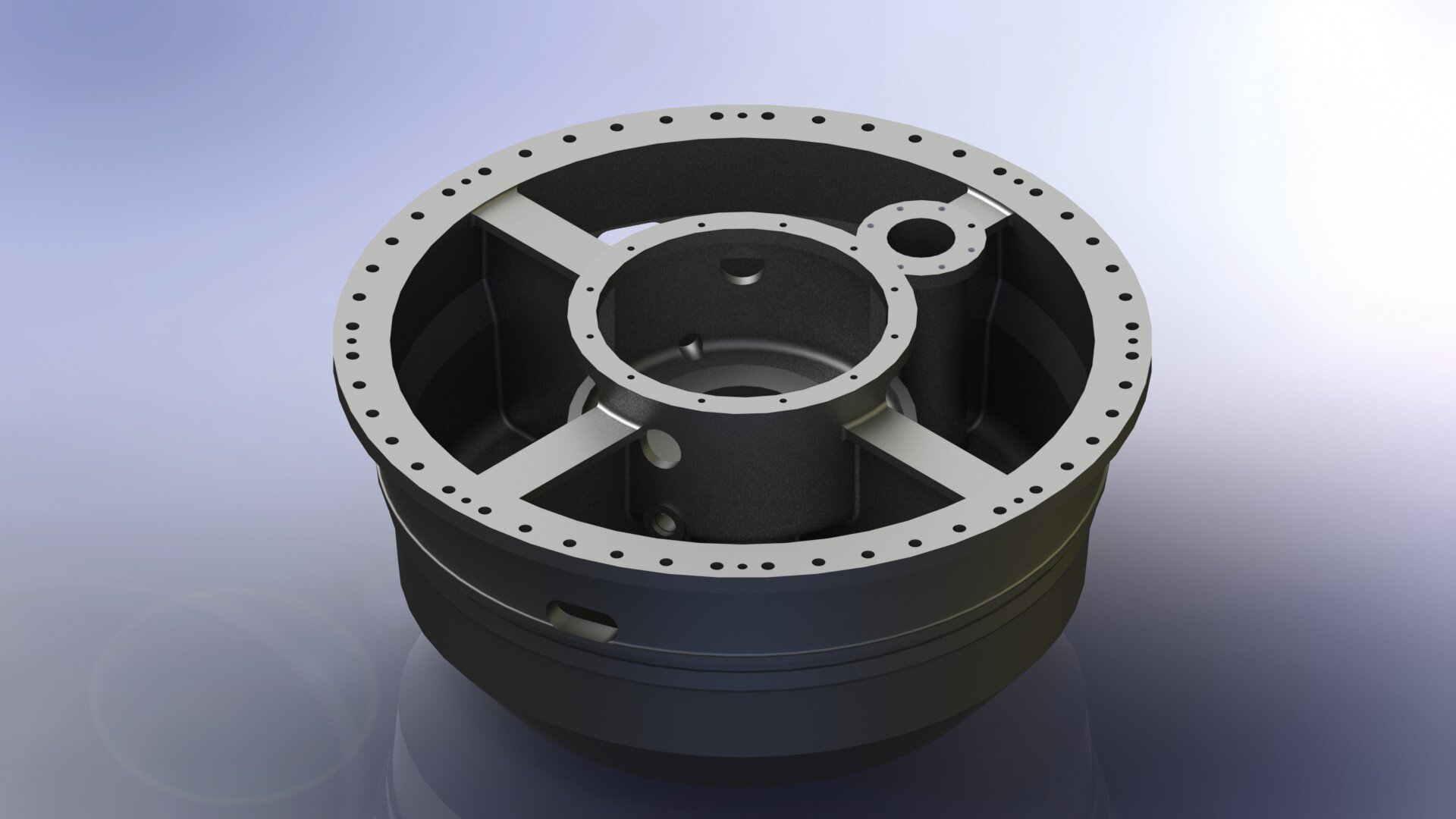

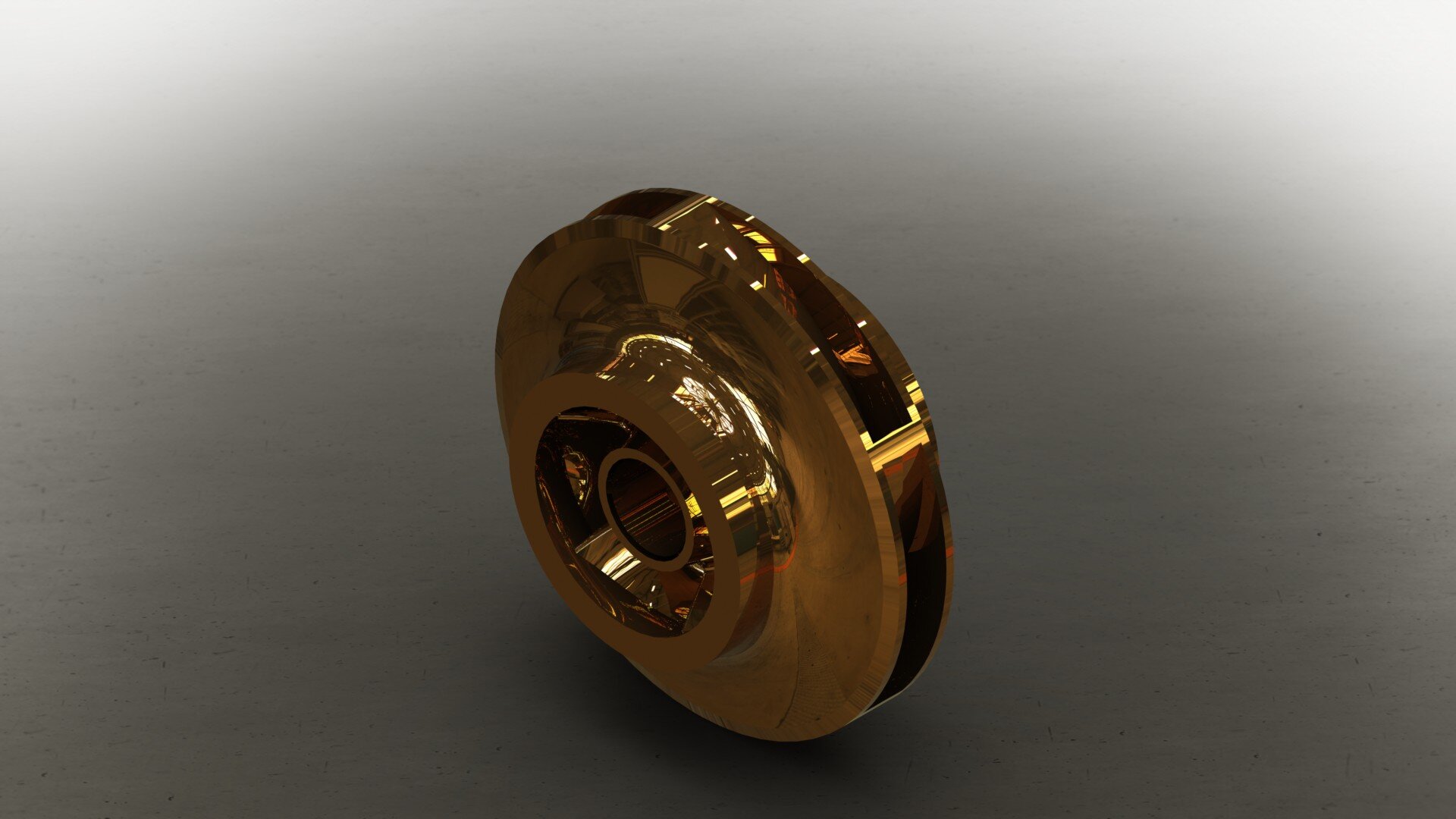

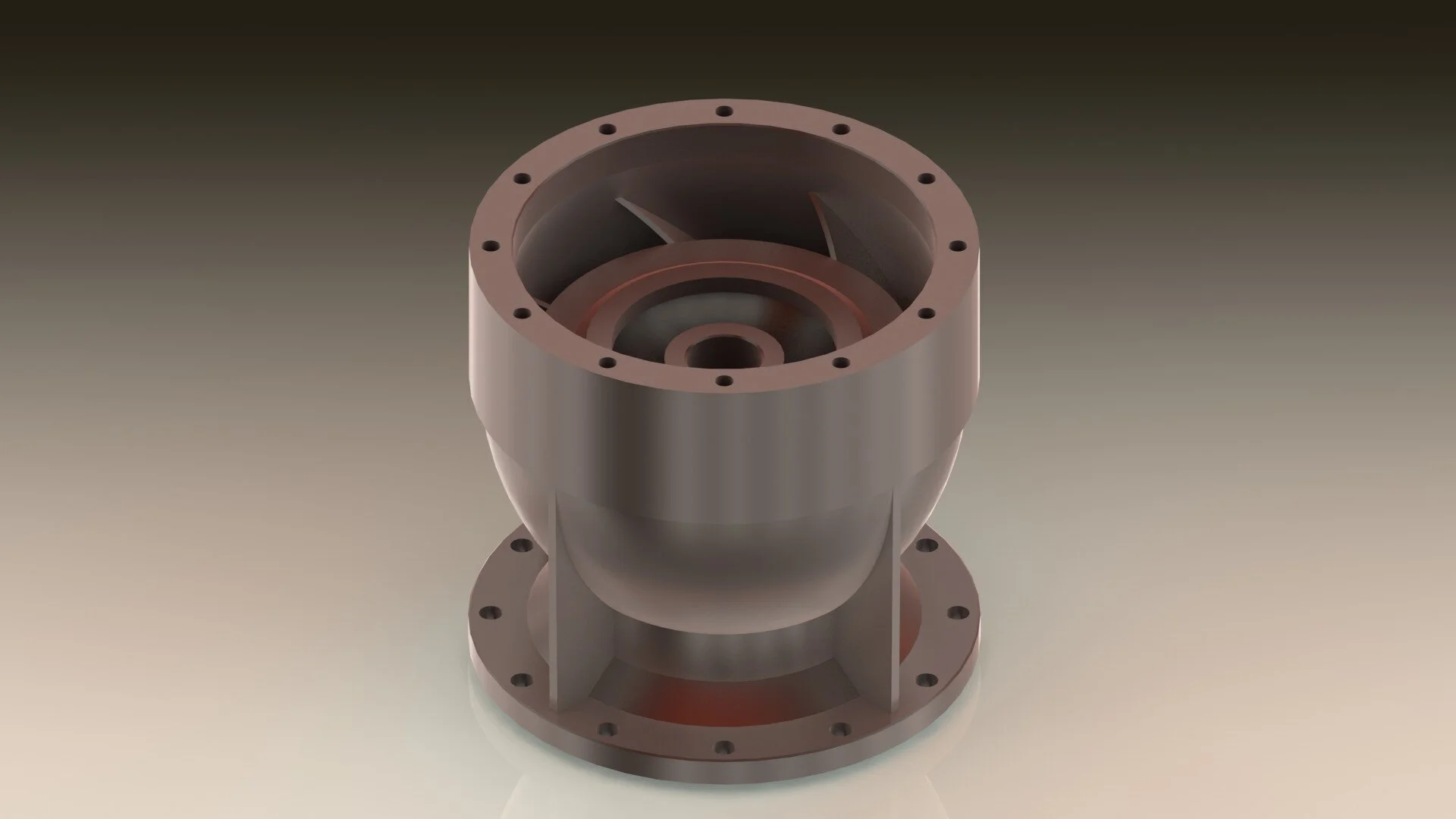

Where traditional 2D CAD and pen and paper fall short, our scanning and modeling technology comes up large. For complex curvatures in impellers, diffusers, bearing housings and more, our 3D scanning technology quickly and accurately captures the details.

RER is highly committed to accurately reverse engineering machinery components. Our staff engineers collectively have over 120 years’ experience in reverse engineering pump parts. RER’s state of the art Leica Absolute Tracker enables us to gather and model any component on both large circulating water pumps, as well as smaller component cooling water pumps.

With end-of-life approaching on many of the pump at aging plants, we provide a cost-effective alternative to purchasing new equipment. New equipment rarely is a match to the existing auxiliary equipment and system requirements. By replicating the same equipment, no changes will need to be made at the plant level.

In conjunction with our pattern shop, we are the foremost experts on reverse engineering castings.

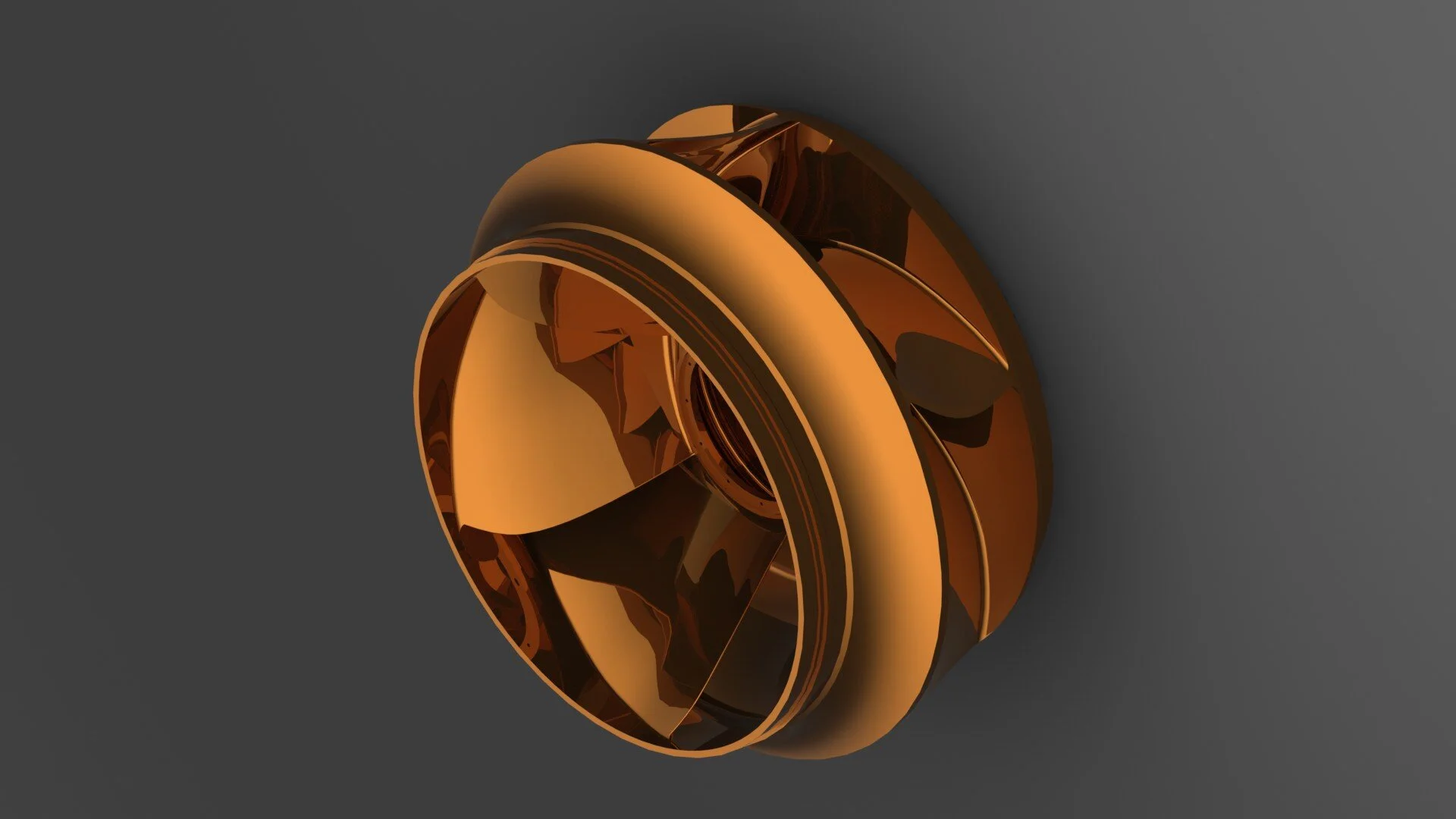

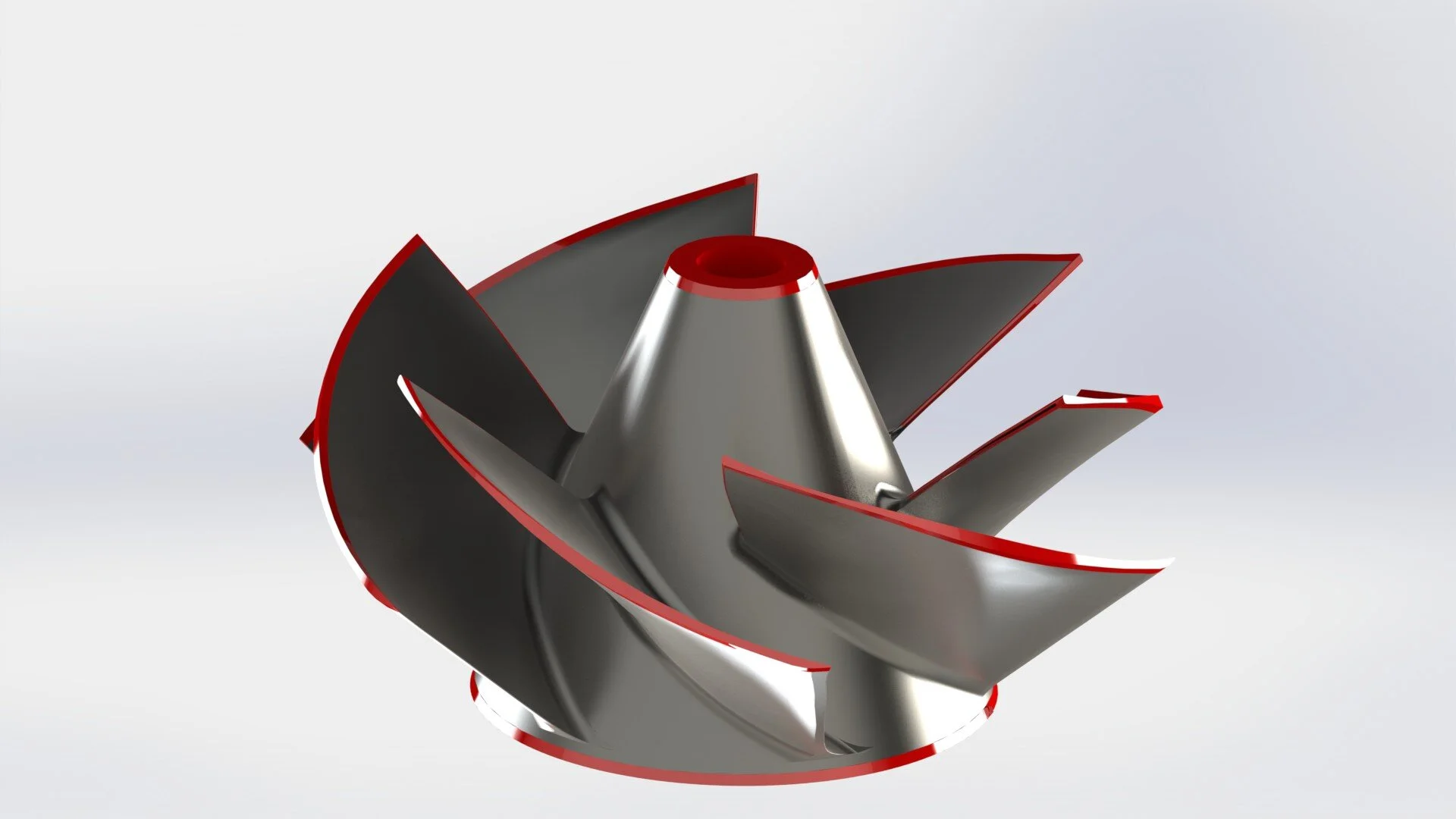

ENGINEERED UPGRADES

Many of these pumps were designed decades ago. Since then, many material upgrades and design changes have come into the market. RER has the knowledge and experience to recommend these upgrades in the appropriate applications.

Why scrap a perfectly good capital investment that’s already paid off, for yet another capital investment that may require major modifications to your intake structures, piping installations, or facility foundation? Legacy designs are built heavier than modern pumps and they were designed to withstand the test of the time and have proven they’ve passed that test. With our expertise, we can combine the best of both worlds.

In the event your system does change and warrants alterations to your pump performance or you’re just looking to squeeze as much efficiency and reliability out of the pumps you already have, we have the experience and the ability to make complimenting changes to your existing pumps. We can alter hydraulic performance for desired changes to the flow, TDH, NPSHr, and efficiency of the rated point for your pump. We have one important thing that most independent facilities lack, the ability to prove the performance of these modifications before it ever leaves our facility with our hydraulic performance test loop. Computation Fluid Dynamics (CFD) and Finite Element Analysis (FEA) have their places in the industry, but everyone can agree that they don’t 100% model real world applications. That’s why the Hydraulic Institute calls for physical modeling on new large pumping systems over CFD and most new capital investment pumps receive a physical test before shipping.

Advancements are being made every day in materials, coatings, and processes. Our flexibility as an independent repair facility combined with our experience and industry relationships allows us to implement those advancements to your aging equipment.

ENGINEERING ANALYSIS

Engineering is an integral aspect of the foundation that our business has been built on since its inception in 1982. With 12 on staff engineers and some of the most experienced people in the industry, we have the ability to help you analyze and solve just about any pump related issue. Whether it’s providing field service, running a CFD or an FEA analysis along with proving modifications in the field, or on our hydraulic test loop, RER has you covered. We don’t rest until we find the root cause of your issues. We pride ourselves on solving issues others have struggled providing solutions for.

Our track record of quality and integrity is highly valued in the nuclear industry’s goal of achieving the “Nuclear Promise.”

SOLID MODELING

RER Engineers generate accurate solid models utilizing point cloud data.

Full parametric models are created and exported to Solidworks. Models can then be modified as needed or imported to FEA/CFD software.

SOLID MODELING VIDEO

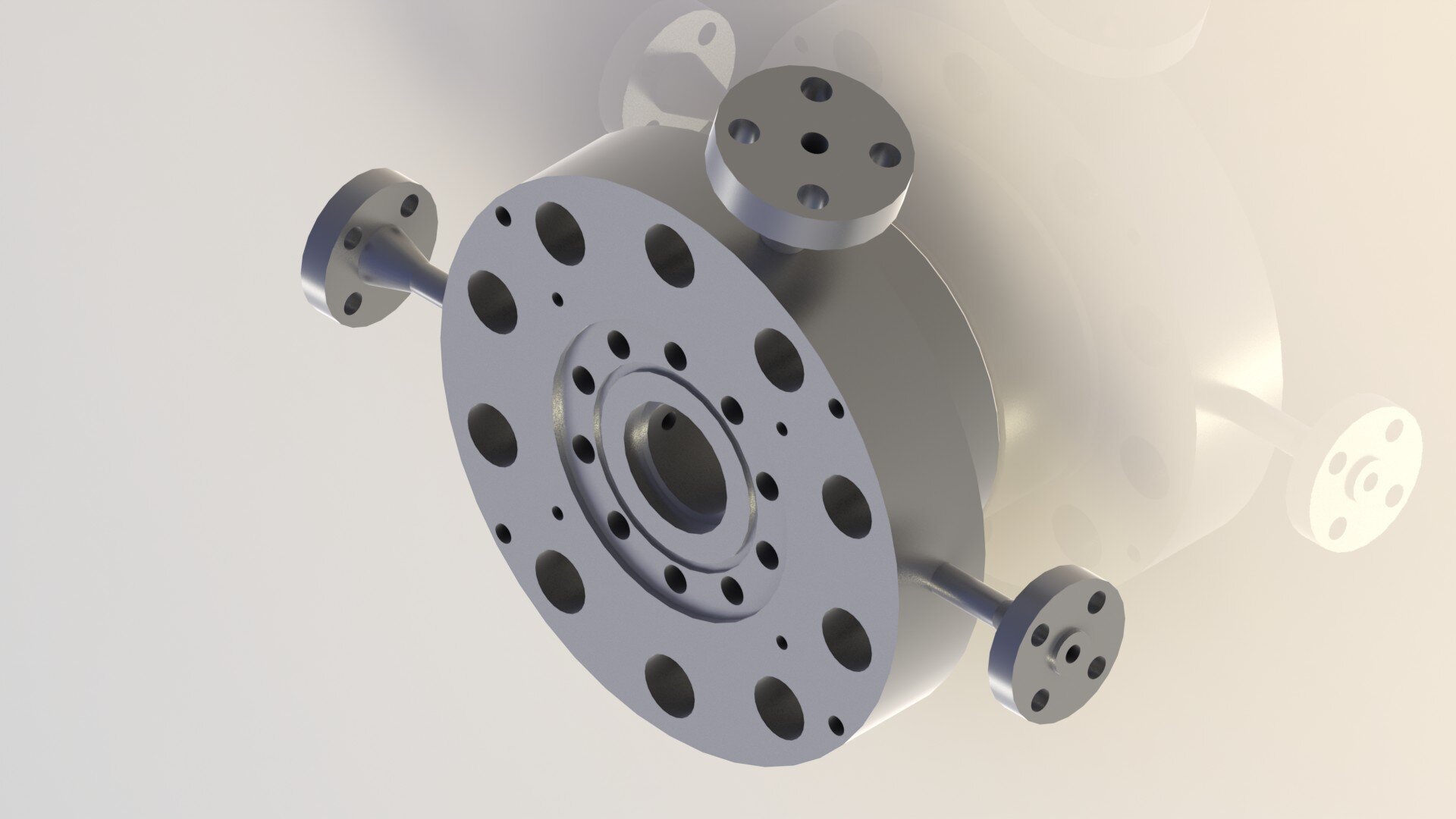

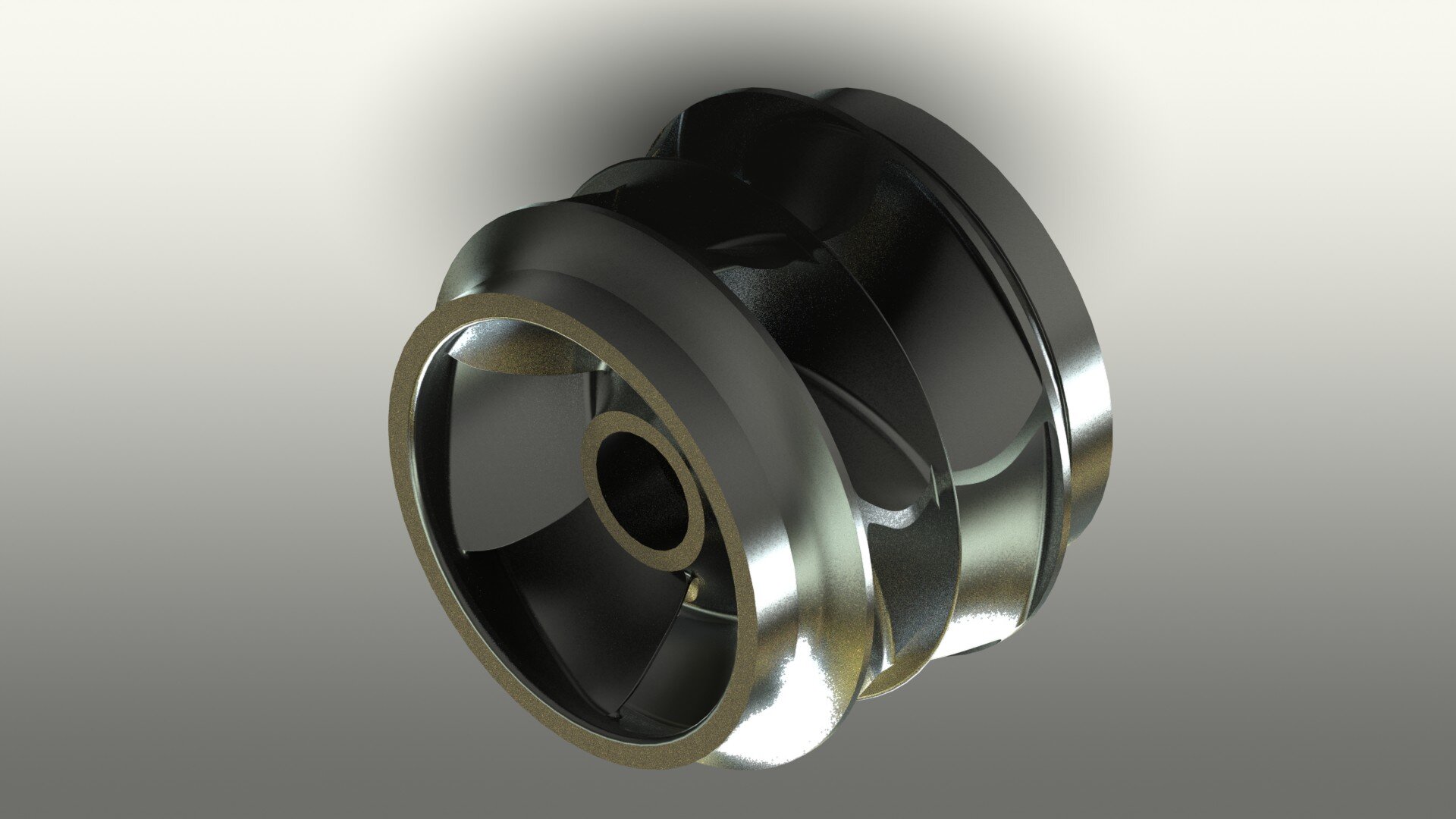

DEVIATION ANALYSIS

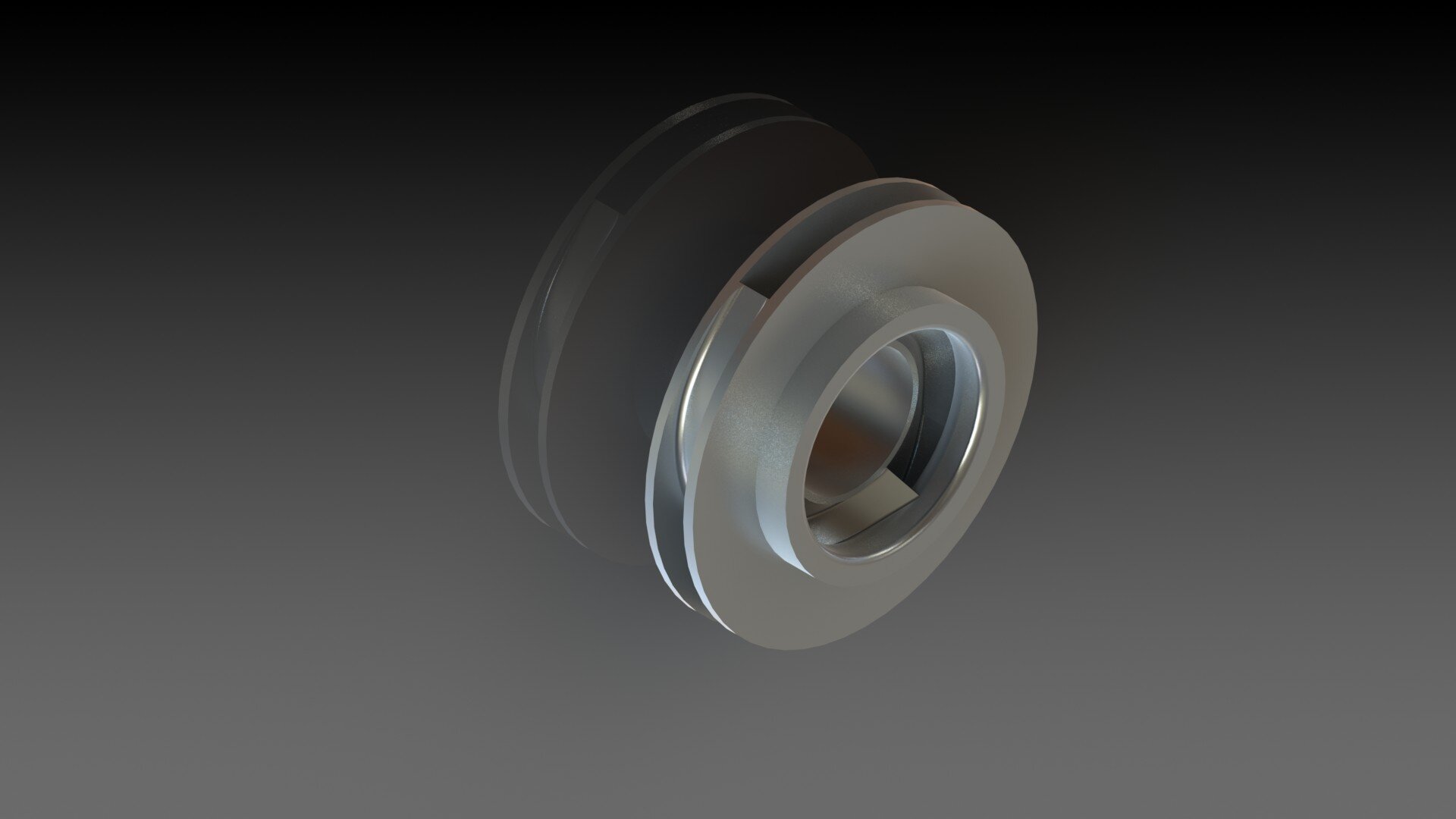

Deviation analysis is used to ensure a geometric match between the old part and the new finish machined part.

Axial cross-sectional deviation analysis is used to verify flow passageway geometry and casting thickness.

Radial cross sectional deviation analysis is used to validate hydraulic characteristics.

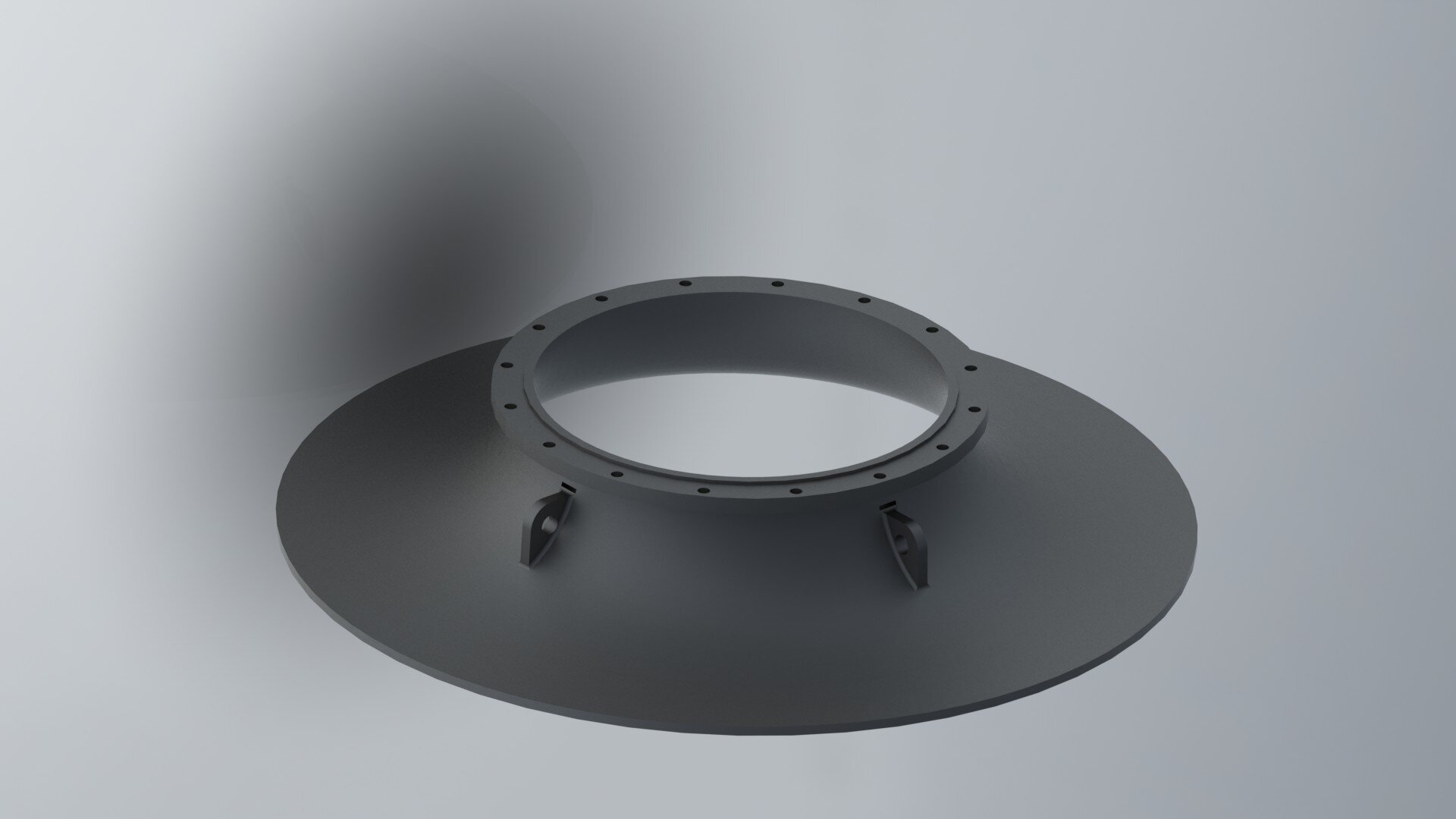

INSPECTION

Split case joint flatness evaluation. This process reveals low spots on the horizontal joint and depicts the gradation using color. It can also identify areas that may require additional bolting force using FEA analysis.